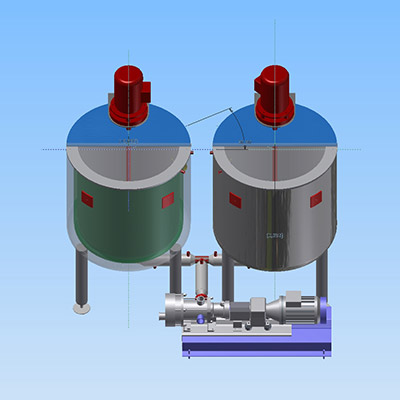

The gelatine is dissolved as a preparation in 2 containers of 100 liters or according to the customer's wishes with a different volume and heated. A special agitator is used to clean the pellets or the raw material (gelatin) without clumping or forming bubbles. On request, we supply the containers complete with pump, platform and piping to the respective consumers. As well as supply and discharge piping.

Construction

Cylindrical container is open at the top and has an attached cover. The lower floor is made of a dished floor. Lower dished bottom as well as cylindrical part heated with hot water. Underneath the containers is a collecting pipe (heated) with 2 disc valves to the pump. The container has an insulated jacket 50mm At the cylindrical part and bottom which is welded and stands on 3 feets ½ "with height-adjustable foot dome. Complete in stainless steel AISI304/316.

Specifications

| Type | Gelatine dissolving Type GT1 + GT2 |

| No. of Tanks | 2 |

| Capacity | 200 Liters / Batch |

| Net volume | ~ 100 Liters |

Dimensions

| Cylindrical Height | ~ 620 mm |

| Diameter | ~ 650 mm |

| Outlet Height | ~ 280 mm |

| Isolation | ~ 50 mm |

Tank connections

| Top | Cover to open (from 1 side foldable with locking device) |

| In the cylindrical part | 1pc Connection for auxiliary heating pre-flow G ½ ", bleed ½ sleeve f. jacket temperature |

| In the cylindrical part | 1 pc connection for temperature sleeve ½“ |

| In the cylindrical part | 4 paving panels at the back and 2 paving panels at the front with M12 thread |

| In the lower bottom | 1pc Connection for trace heating (drain) G ½ " |

| In the lower bottom | 1 Connection of the mass outlet DN 40 DIN 11851 with cone and compression nut |

| In the lower bottom | 1 disc valve DN 40 each with external thread on both sides |

| In the lower bottom | 41 Connection pipe with T-piece to the pump (including heating jacket with connections G ½“ and 3-piece stabilisations DN 40 |

Material thickness and quality

| Surface | inside welded seems sanded, outside glass bead blasted. |

| 1 pc conneciton pipe – outlet | DN 40 with heating double jacket. Heating medium is warm water |

| 1 pc connection pipe – inlet (water) | DN 25 with three way Koltek valve DN 50 |

| 1 Stück Podest in L-Form with steps | Consisting of 2 podiums./td> |

New sugaring line for Fazer Finnland

Company Fazer in Finland has received a new after-treatment line (processing of confectionery) The scope of delivery included...

Read More...