We have a tradition of innovation

Next Level has been our program since 1947.

As a family-owned company, we have been shaping special plant construction in the food sector for decades.

ten Brink has been moving with the times since 1947 and always tries to be one step ahead.

We have been successfully developing product and process innovations for the food industry for three generations.

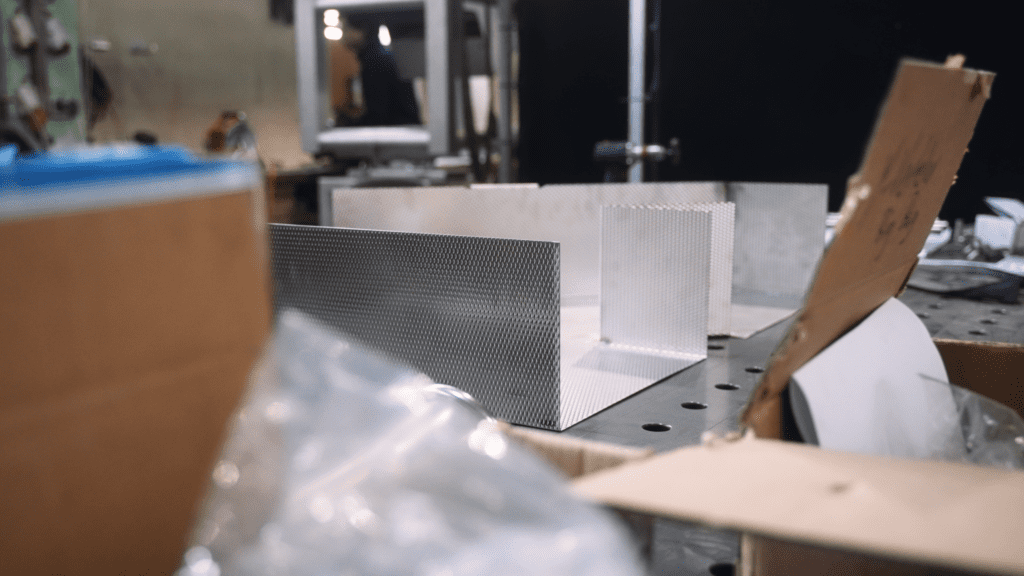

Individual solutions are our specialty.

There is no such thing as “can’t”.

As a family business, we are rooted in Nuremberg.

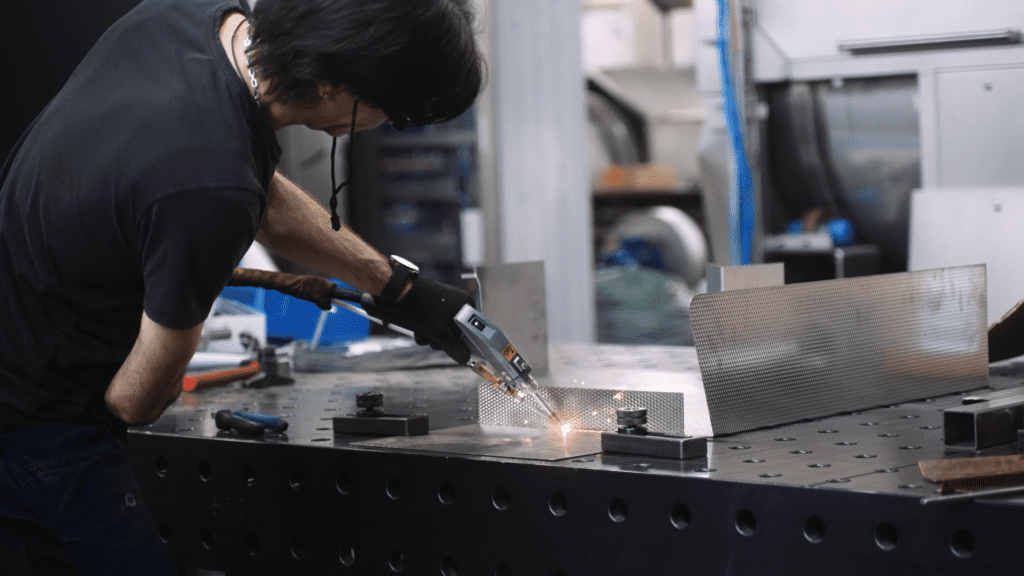

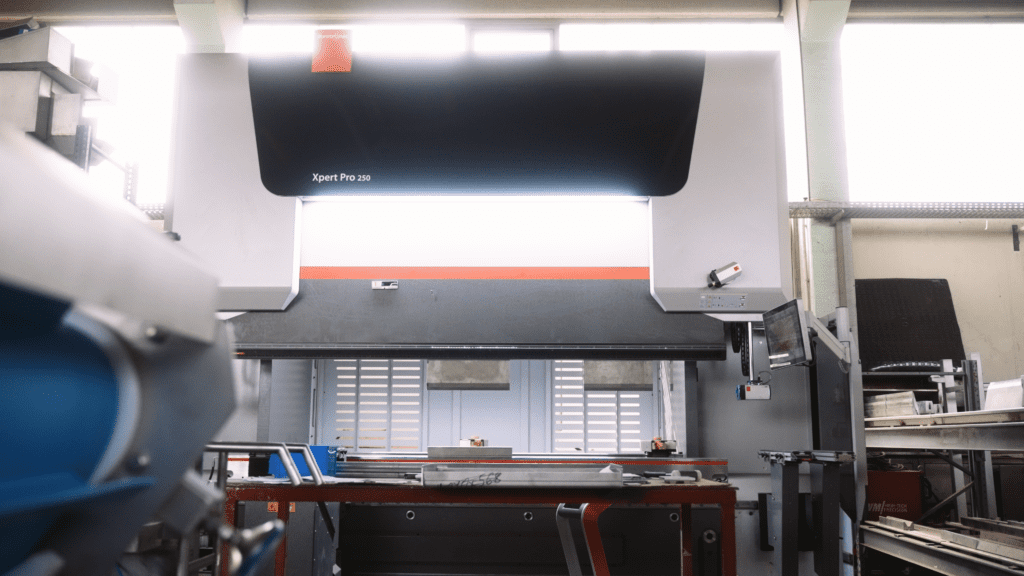

We can manufacture almost 100 percent of our products directly on site at our factory.

Our lean organizational structure allows us short decision-making processes, fast response times and the flexibility to find and develop completely new solutions for our customers.

Our growing team combines the expertise of skilled workers, certified welders, engineers and specialists in assembly and commissioning.

From the initial inquiry through to commissioning, your direct contacts are the two managing directors: Sascha ten Brink and Alexander Reuß.

Your advantage as a customer: direct communication, quick decisions and personal support on site.

He joined the family business in 2004 and founded ten Brink Engineering & Consulting GmbH & Co KG with his father in 2005.

He can now look back on over 20 years of specialist knowledge and experience in plant engineering.

In 2016, he expanded production to Asia with the founding of ten Brink Engineering India Private Limited.

He was previously operations manager at ten Brink Engineering & Consulting GmbH & Co. KG for four years and is very familiar with the company’s production program.

Alexander Reuß is a trained automotive mechatronics technician and has a degree in mechanical engineering.

After completing his training, he initially joined his parents’ company in the metalworking and processing sector.

After graduating, he founded and managed his own company for sheet metal working and processing until 2019.

Assistant to the management

since 2024 Project manager

Stay up to date with our newsletter about features and publications.