Sweet, sweeter, unique

Special systems for confectionery production

Your recipes are unique – and so are our systems for confectionery production.

Sometimes even unique worldwide.

We have been working with leading companies in the confectionery industry for many years, developing highly customized solutions that are unique in the world.

Use our expertise to take your confectionery production to the next level.

A more energy-efficient system or greater automation?

A new product and a new production line?

From individual solutions to complete solutions, we offer you everything you need for the production of sweets with and without starch, post-treatment with sugar or oil.

We only use the best materials and components in our production lines – for long-lasting, low-maintenance quality, efficient cleaning and, above all, competitive products on your side.

Kitchen facilities

Weighing and mixingHeating and vacuuming

Dosing systems

Precise dosing: Colorants, aroma, other ingredients Pour lump-free

Conveying & storage

Efficient transportation Safe and hygienic storage

Aftercare

Dry optimally Treat surfaces gently Sugar-coat or oil

Laboratory systems

In small quantities: test, analyze and develop something new

Next-level systems for your confectionery production

Kitchen facilities

Preparation is everything

Determine the size, shape and equipment of your storage tanks for ingredients, raw materials and products.

Horizontal or vertical design, round or square containers, with a conical base…

Kitchen facilities

Preparation is everything

With our kitchen equipment, we offer you individual solutions for preparing and processing ingredients.

From stainless steel containers with different capacities, heated and unheated tanks with agitators and pump systems to intermediate containers with sieve inserts and piping for the supply and discharge of ingredients.

Also in the portfolio: complete cooking systems that work under pressure or vacuum.

Weighing, mixing, heating and vacuuming – you decide which stations you need.

We build solutions to suit your ingredients, including connection points for upstream and downstream production steps.

Gelatine processing

A special agitator guarantees that the gelatine is dissolved without lumps or bubbles.

We build stainless steel tanks with the capacity you need.

Complete with pump, platform and piping on request.

Starch processing

When producing with starch, our system ensures the correct moisture content and lump-free mixing of the starch.

We build: different sized tanks, sieve inserts, pump, platform, piping.

Vegan pectin and agar processing

Expand your confectionery production to include the processing of vegan gelling agents such as pectin and agar-agar.

We guarantee smooth processing with our systems.

Recycling processing

Defective products and residual mass are fed back into the process and melted down again.

Recycling processing allows you to reduce waste and save costs in the long term.

Cooking systems

For a continuous cooking process under vacuum, we build stainless steel cooking systems that can be multi-storey and include tanks of up to 200 liters and cooking kettles with agitators.

Set stove

If you work in batches, we will design the right batch stove for you.

You can enter and process different recipes and cook in batches under pressure and vacuum.

Dosing systems

accurate to the gram

One gram can make a big difference when it comes to the ingredients for gummies.

Be it in taste, color or texture.

Our dosing systems are at the heart of the…

Dosing systems

accurate to the gram

One gram can make a big difference when it comes to the ingredients for gummies. Be it in taste, color or texture.

Our dosing systems are the heart of the confectionery production process and dose even the smallest quantities with high precision to ensure that your secret recipe works.

They work either with volumetric or gravimetric principles.

Both ensure bubble-free and lump-free mixing of the individual ingredients and our mixing tanks prevent sticking at the edges.

This reduces subsequent pouring errors and reduces ingredient loss.

Our complete solutions include thorough and fully automatic cleaning before recipe changes.

Volumetric dosing systems

Sensitive diaphragm pumps dose very small quantities exactly according to your recipe and pump them into mixing containers.

We offer: Complete solutions from manual pre-dosing to fully automatic dosing and cleaning.

Gravimetric dosing systems

The best on the market: dosing takes place from top to bottom and uses gravity by means of special dosing valves and weighing cells.

The modular system allows the stations to be extended up to eight-fold dosing.

Foam dosing systems

The base for foam products has a different viscosity to that for jelly products.

No problem for us.

Our foam dosing systems also work with high precision and ensure bubble- and lump-free pouring.

Aftercare

Efficient finishing

In post-treatment, your products are given the finishing touches by sugaring or oiling.

Regardless of which finishing you use, we have our systems for both processes…

Aftercare

Efficient finishing

In the post-treatment stage, your products are given the finishing touches by sugaring or oiling.

Regardless of which finishing you use, we have optimized our systems for both processes.

In the sugaring system, we integrate vaporizing belts that prepare the items for sugaring by applying steam without damaging the surface.

Only as much sugar or oil as is necessary is added to the sugar and oil drums.

In our drying tunnel, you can shorten the time between sugaring and packaging.

With our systems, you save ingredients, energy, time and manpower and get a uniform surface treatment that looks good.

Sugaring systems

The surface of the product is gently prepared for sugaring with steam on our advanced steaming belts.

The hygienically designed sugar drum guarantees even wetting with sugar.

Oiling systems

Our oil drums ensure that your products shine.

With a special oil pump, only as much oil is added as necessary.

The drum is easily accessible from all sides for uncomplicated cleaning.

Article cleaner (Candy Cleaner)

Starch is used particularly in gum and jelly products to prevent the individual items from sticking together.

The Candy Cleaner removes excess starch from your product for optimum post-treatment.

Drying system

Into the drying tunnel after sugaring.

Because it saves you time, energy and space.

No extra drying room and drying time after sugaring and you can pack your product faster.

Conveyor systems

Nothing works without belts

We turn a simple conveyor belt into something special: with quality awareness and an eye for detail.

We use the latest and best materials to minimize wear and tear and…

Conveyor systems

Nothing works without belts

We turn a simple conveyor belt into something special: with quality awareness and an eye for detail.

We use the latest and best materials to increase wear and abrasion resistance.

We do not rely on standard components.

Hygienic bearings encapsulated on all sides are lubricated for life and are dust and waterproof.

Aseptic motors are protected against splash water and chipped paint.

You remain flexible with our modular design.

We build in the dimensions and variants you need for your production process.

They can also be combined with a robot feed system.

Easy cleaning and maintenance are a matter of course.

Transport system with PU Intralox belt

We take the choice of belt seriously.

With polyurethane (PU), we use a very hard-wearing material that is resistant to oils and greases.

Longer belt life and easy cleaning guaranteed.

Troughed conveyor belts

A safe all-rounder for bulk materials: The troughed conveyor impresses with its simple design and solid construction.

Product losses are minimized thanks to the smooth running.

Elevators

From Z-conveyors and vertical conveyors to bucket conveyors.

Space-saving designs and time-saving transportation.

Buffer strips

Bridge breaks: Buffer the transportation of your products automatically.

Buffer belts allow you to bridge breaks without stopping production and increase cost efficiency.

Distribution belts with switch

Stay flexible: Configure your conveyor system for maximum flexibility.

Distribution belts with diverters enable changes of direction for product transport and the separation of products.

Wiegebänder

Well weighed: With the weighing belts, you can convey bulk material simultaneously and weigh it dynamically.

We support you in adjusting the system to ensure weighing accuracy.

Vibratory conveyor

Several work steps in one: the vibratory conveyor makes it possible.

For example, the separation of articles and the alignment of articles via a belt.

We use electric, pneumatic and magnetic vibratory drives.

Conveyor belts with modular belt

We use different modular belts with open and closed belt surfaces depending on the application.

We mostly use belts made of blue polypropylene (PP).

They can be installed in elevators and flights with an edge-free zone.

Robot feeding system (separation)

With pick and place robots, you can increase your performance for products consisting of several individual parts.

High speed and accuracy are no problem for our feeding system.

It performs the perfect preparatory work and reduces the error rate.

Container

All sizes and special solutions

Stainless steel containers have a long tradition with us.

We have been producing them since 1947. Your customer requirements are decisive, because we design the containers individually according to…

Container

All sizes and special solutions

Stainless steel containers have a long tradition with us.

We have been producing them since 1947.

Your customer requirements are decisive, because we design the containers individually according to your needs.

From small special solutions, for example as citric acid containers, to large containers with a capacity of up to 50,000 liters.

With heating, with agitator, round or square.

Everything is possible.

Storage tanks

Determine the size, shape and equipment of your storage tanks for ingredients, raw materials and products.

Horizontal or vertical design, round or square containers, with conical or dished base. Anything is possible.

Tanks with agitators

We can install agitators in the stainless steel tanks on request.

Depending on the application, for example: anchor agitators, propeller agitators, dispersing agitators, agitators with scrapers, etc. We focus on quality when choosing our suppliers.

Heated tanks

The tanks can be heated in various ways as required: with Thermplate, half-pipe coils, double-walled with hot water or steam.

Laboratory systems

Development of new recipes

Further developments and new developments often give you the competitive edge in the confectionery market.

In laboratory facilities, you can develop new recipes, produce small quantities of…

Laboratory systems

Development of new recipes

Further developments and new developments often give us a competitive edge in the confectionery market.

In laboratory systems, you can develop new recipes, produce small quantities of sugar confectionery and carry out product tests.

We design and build your laboratory system completely from stainless steel with all components and stations as in the real production process.

Laboratory cooking systems

We design a complete solution for the production of small quantities.

With boiling kettle with agitator, vacuum processing, instruments such as temperature, vacuum and pressure gauges, regulator and light.

Laboratory glucose line

Test the post-treatment of your products by saccharification with a mini system that simulates the entire saccharification process.

Laboratory & lubrication line

Post-treatment by oiling can also be tested in the laboratory.

The smaller equipment in our laboratory oiling line fits into a small space.

Innovation

The solution you need does not yet exist? We will design and build them for you.

Our claim: high-end solutions for you that are energy-efficient, easily meet all hygiene standards and improve your production processes.

We regularly develop new special solutions and optimize where possible.

In the confectionery sector, we have created a time and energy-efficient alternative to the drying room after sugaring with our drying system.

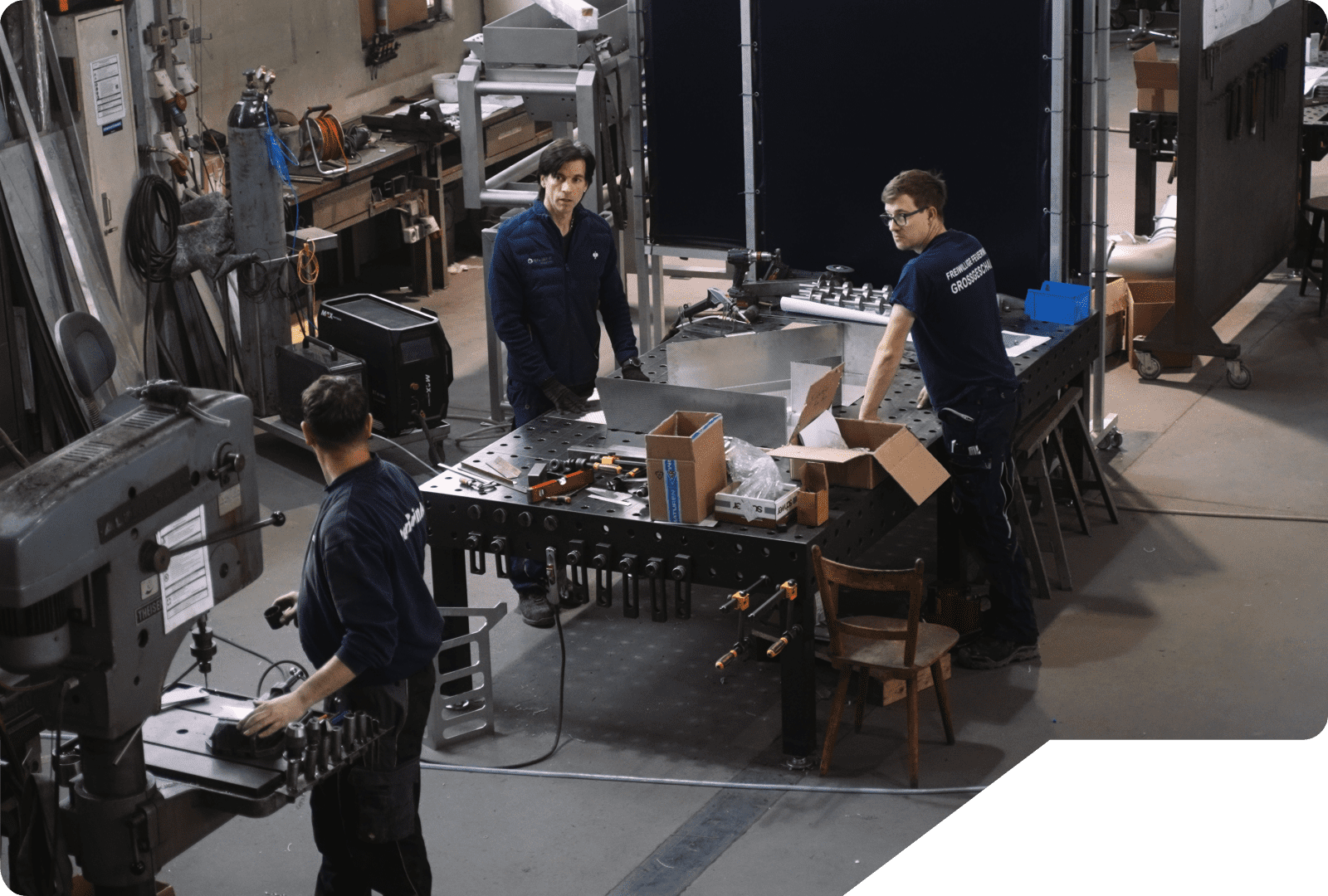

How we work

We support you from the first sketch through construction to commissioning and maintenance for individual systems and complete production lines. With our team of skilled workers, certified welders, engineers and specialists for assembly and commissioning.

Career

We are only strong and remain innovative with experts and specialists. Become part of the ten Brink family in Nuremberg.

Talk to us

Subscribe

Stay up to date with our newsletter about features and publications.