Plant engineering

From the first sketch to maintenance

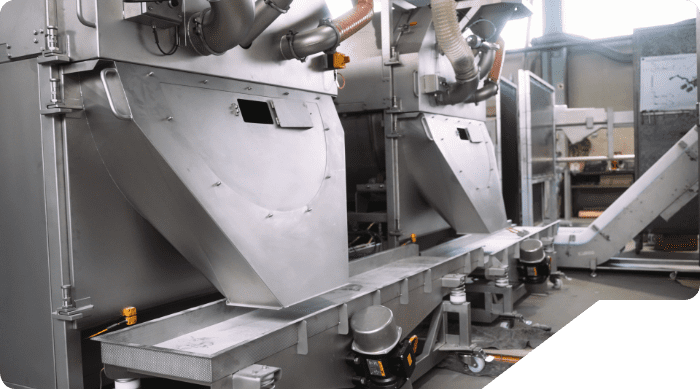

You have the good recipes and optimize food processing - we build the ideal production line for you.

How we work with you

Energy-efficient, innovative, space-saving, durable and, above all, customized to your needs.

We plan, design and build your special system and are also at your side during commissioning. We guarantee support throughout the entire process, always personally available: from the planning and assembly of your production system with components that build on each other, to construction, installation and training of your employees on site.

Our work is:

Precise

Flexible

High quality

Innovative

Efficient

Clarification of requirements

We start personally

It all starts with a conversation with you. We want to get to know and understand your wishes and experience, your need for optimization and innovation in detail. During an on-site appointment, we check your specific circumstances, into which our system will later be smoothly integrated. If required, we can take over the complete project planning and coordination with other trades.

-

Request & Budget

-

On-site appointment

-

Quotation preparation

Planning & construction

We find solutions

Your and our experience is incorporated into the planning phase. We coordinate the details of every design. This is the only way to create a solution that takes all your requirements into account. From safety, hygiene and capacity to legal requirements. Once the initial 2D/3D design has been agreed, we move on to the 3D design. The spatial representation gives you an overview of all the details. With line planning in 2D, we maintain an overview.

-

2D and 3D designs

-

3D design & line planning

-

Prototyping

Manufacturing

Your system is created

We manufacture your system step by step in our hall in Nuremberg. Precisely and to the highest technical standard with our laser welding system and our edging, rounding, turning and milling machines. We work together with suppliers who also use the latest technologies in the manufacture of their components. At the end of the production phase, your system is fully assembled in our hall before final acceptance takes place with you.

-

Production & assembly in our hall

-

Live previews in Nuremberg

-

Final acceptance (facturing acceptance test)

Installation

Now it's your turn

After successful acceptance, we bring your system safely to your production facility. Our installation team of assembly and commissioning specialists will set up the system at your site and support you with all connections and integration into your existing processes. We train your employees and provide you with all documentation, certificates and attestations for your new system.

-

Installation & commissioning at your site

-

Training your employees

-

Production support during system start-up

Maintenance

We remain at your side

We remain at your side after commissioning. Many of our systems are custom-made products for which we are the experts. We are always available for support, whether you have questions about system operation or control software. We also carry out repair services for you, even though we build our systems in such a way that this rarely happens. If required, you can conclude a maintenance contract for regular maintenance.

-

Maintenance contract

-

Software support

-

Repairs

Talk to us

Subscribe

Stay up to date with our newsletter about features and publications.